Now you will be redirected to the Supra EL family

![]() Joe Wurtz about wing servo instalation

Joe Wurtz about wing servo instalation

![]() Wing Template for Sprite and Supra

Wing Template for Sprite and Supra

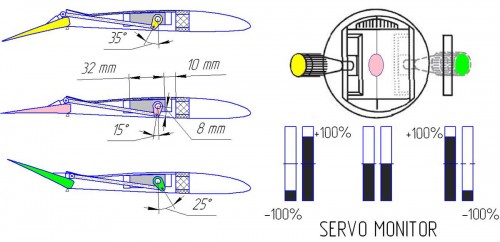

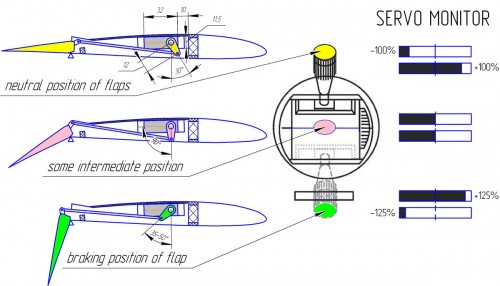

To correctly set up flap an aileron deflections in relation to the TX sticks movement, we recommend the following arrangement:

The photographs below shows an example of setting the flaps for the rocking chair with a shoulder 7.5 mm at the Futaba T12FGA transmitter.

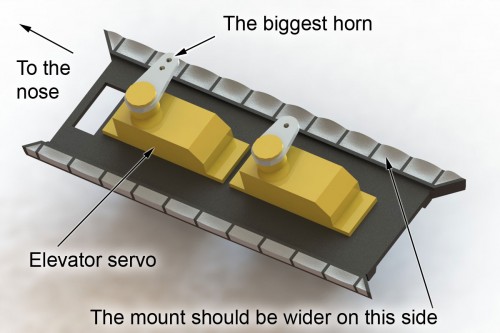

Before assembling, measure your receiver, battery and other equipment, then decide on the location of the elevator and rudder servos.

Both pushrods are located on the starboard (right) side of the fuselage. The space on the other side will be taken by the wires from the wing servos.

We recommend using a ball joint for the rudder servo, which allows to place the rudder and elevator pushrods above one another, as shown in the picture.

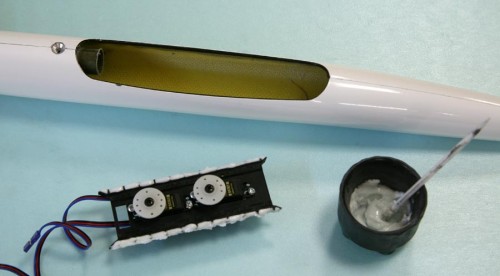

Sand the inside of the pod in the area, where the servo tray will be installed. Mix epoxy with your favorite filler (microballoons, chopped fibers, colloidal silica, etc.) and apply it liberally to the servo tray rails.

Insert the servo tray/rails assembly with installed servos into the pod. The rails should be shaped so that the bottoms of the servos (e.g., JR DS368) touch the bottom of the fuselage and no deformation of the fuselage cross-section occurs. If needed, apply extra epoxy over the rails/fuselage joint.

Remove the excess of the epoxy from the inside of the pod with a cotton swab or paper towel. The outside of the fuselage may be cleaned with alcohol or gasoline before the epoxy is cured.

The servo tray is mounted on its rails with 4 supplied screws. The receiver and the battery should be wrapped in protective foam before installing.

After finishing assembly of the pod, glue the tail boom to it with epoxy, ensuring that the horizontal stabilizer is parallel to the wing. The glueing surfaces are pre-sanded for better adhesion.

If there is excessive gap between the pod and the boom, wind some thin thread over the end of the pod.

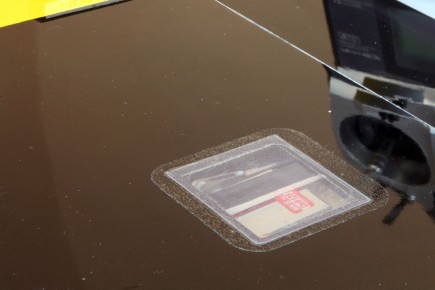

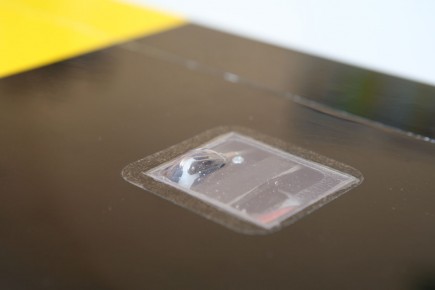

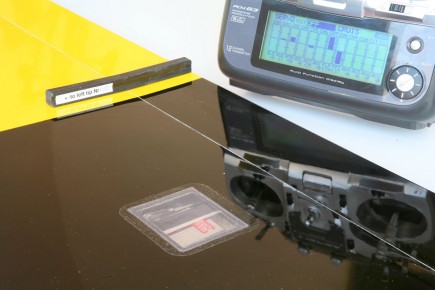

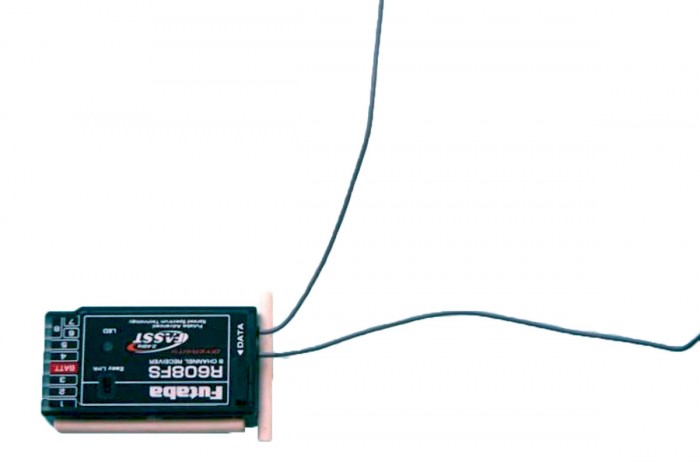

Receiver protection, Futaba 2.4 GHz example :

1) Cut pieces of pushrod sleeves and glue them with CA to the receiver case—they will house antenna tips (which should be oriented at 90 degrees to each other);

2) Insert antenna tips into the sleeves and fix the antennas in place with sticky tape.

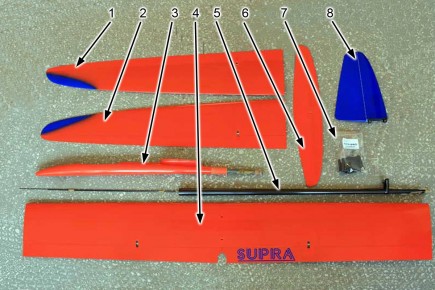

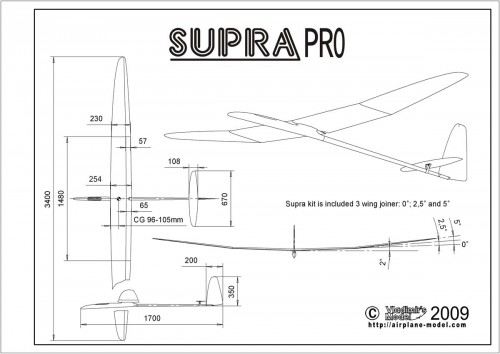

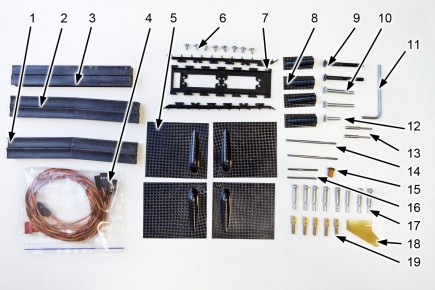

Contents of Supra PRO Competition kit

Contents of accessories kit:

1 - Wing joiners with an angle of 5°;

2 - Wing joiners with an angle of 2,5°;

3 - Wing joiners with an angle of 0°;

4 - Wires for connect the receiver to the wing connectors;

5 - Wing servo hatches with fairings for servo horns;

6 - Servo tray mounting screws;

7 - Fuselage servo tray and rails;

8 - Top surface fairings for flaps and aileron pushrods;

9 - Forward wing mounting screws М4х40(with one spare);

10 - Rear wing mounting screws М4х30(with one spare);

11 - Wrench for screws 2.5 mm;

12 - Ballast holding screw М4х16;

13 - Couplers M2 for carbon rod;

14 - Flap pushrods М2х50;

15 - Nut for the horizontal stabilizer V-mount;

16 - Aileron pushrods М2х30;

17 - Aileron, flap and tail clevises М2;

18 - Wing control horn;

19 - Ailerons and flaps control horns.

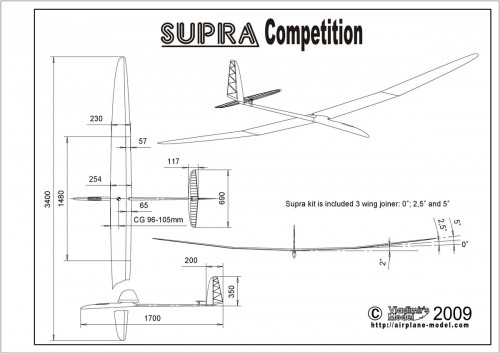

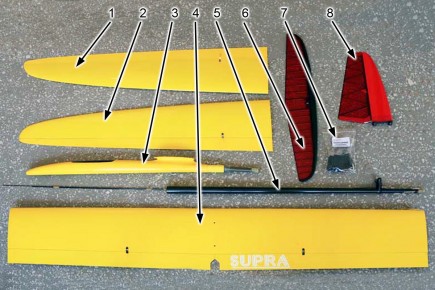

Contents of part kit:

1 - Left wing tip;

2 - Right wing tip;

3 - Fuselage;

4 - Central panel;

5 - Tail boom;

6 - Stabilizer;

7 - Contents of Supra PRO Competition kit;

8 - Vertical stabilizer.

Contents of Supra PRO kit

Contents of accessories kit:

1 - Wing joiners with an angle of 5°;

2 - Wing joiners with an angle of 2,5°;

3 - Wing joiners with an angle of 0°;

4 - Wires for connect the receiver to the wing connectors;

5 - Wing servo hatches with fairings for servo horns;

6 - Servo tray mounting screws;

7 - Fuselage servo tray and rails;

8 - Top surface fairings for flaps and aileron pushrods;

9 - Forward wing mounting screws М4х40(with one spare);

10 - Rear wing mounting screws М4х30(with one spare);

11 - Wrench for screws 2.5 mm;

12 - Ballast holding screw М4х16;

13 - Couplers M2 for carbon rod;

14 - Flap pushrods М2х50;

15 - Nut for the horizontal stabilizer V-mount;

16 - Aileron pushrods М2х30;

17 - Aileron, flap and tail clevises М2;

18 - Wing control horn;

19 - Ailerons and flaps control horns.

Contents of part kit:

1 - Left wing tip;

2 - Right wing tip;

3 - Fuselage;

4 - Central panel;

5 - Tail boom;

6 - Stabilizer;

7 - Contents of Supra PRO Competition kit;

8 - Vertical stabilizer.

Recommended equipment not included in the kit

2) Bag for model;

3) Batteries:

Sanyo 4 cells NiMH 1500 mAh;

Sanyo 5 cells NiMH 1500 mAh;

4) Transparent servo hatches;

5) Servos :

MKS DS6125; JR DS378; AIRTRONICS 94761Z – for flaps, horizontal stabilizer;

JR 285MG; MKS DS6125 – for ailerons and rudder;

6) Reciver:

Spectrum AR9000 (JR R921);

Futaba 6008HS;

Weatronic Micro 8 Dual Receiver 2.4 Dual FHSS.

You can selected parameters you need using the following comparative table.

|

Comparison of Different Models from Supra Family |

||||||||

|

Color the model |

SUPRA PRO Competition |

SUPRA PRO |

||||||

|

Model version |

Spread |

Hard Spread |

Glass |

Carbon-glass |

Spread |

Hard Spread |

Glass |

Carbon-glass |

|

Aerodynamic parameters |

||||||||

|

Length |

1700 mm (66,93") |

|||||||

|

Wing span |

3400 mm (133,85") |

|||||||

|

Wing area |

69,34 dm2 (1052 in2) |

|||||||

|

Wing airfoil |

AG 40/ AG 41/ AG 42/ AG 43 |

|||||||

|

Wing aspect ratio |

16.67% |

|||||||

|

Horiz. stabilizer area |

6,2 dm2 (96,1 in2) |

5,8 dm2 (89,9 in2) |

||||||

|

Horiz. stabilizer aspect ratio |

7.68% |

7.74% |

||||||

|

Horiz. stabilizer airfoil |

HT 14/ HT 15 |

|||||||

|

Vertical stabilizer area |

4,9 dm2 (76 in2) |

|||||||

|

Vertical stabilizer airfoil |

HT 13/ HT 12 |

|||||||

|

Vertical stabilizer aspect ratio |

2.5% |

|||||||

|

Control surfaces |

ailerons, flaps, full-flying stabilizer, rudder |

|||||||

|

Weights, gr** |

||||||||

|

Pod |

190 |

|||||||

|

Tail boom with pushrods and V-mount |

68 |

|||||||

|

Wing central section (with wires) |

540 |

565 |

585 |

730 |

540 |

565 |

585 |

730 |

|

Pair of wing tips |

330 |

356 |

350 |

330 |

356 |

350 |

||

|

Vertical stabilizer & rudder |

33 |

40,5 |

||||||

|

Horizontal stabilizer |

26,3 |

34,6 |

||||||

|

Fairings, control horns, etc. |

82 |

|||||||

|

Empty airframe |

1259,3 |

1330 |

1340 |

1440 |

1345 |

1410 |

1425 |

1525 |

|

AUW (All Up Weight) * |

1530 |

1590 |

1600 |

1700 |

1615 |

1675 |

1685 |

1785 |

|

Wing loading,g/dm2 * |

22 |

23 |

23 |

24,5 |

23,3 |

24,1 |

24,3 |

25,7 |

|

Price, EUR |

||||||||

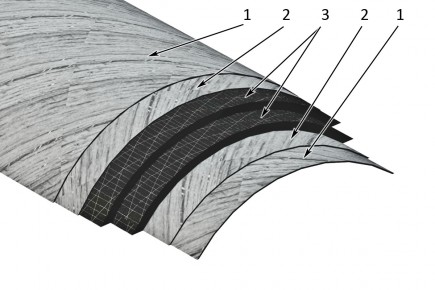

Following numerous design studies, in the Spring of 2009, we introduced optimized wing spars for Supra PRO family, which increased wing stiffness while reducing weight. New wing spars are baked in an autoclave in special molds from CF pre-preg. We use high strength carbon fiber IMS 65.

Vladimir’s Model’s space age design employing Rohacel core for the flaps results in unbelievably light and incredibly strong thin wings. Combination of the right stiffness and weight eliminates aileron flatter even at extreme speeds.

Supra Spread and Supra Hard Spread are built with bi-axial Spread Tow carbon we make in-house from high strength carbon fiber IMS 65. The weight of the finished CF composite is only 38…40 g/m², which results in lighter and stronger parts.

Supra Spread is ideal for morning flying—it has the lowest weight and sufficient stiffness for fast starts.

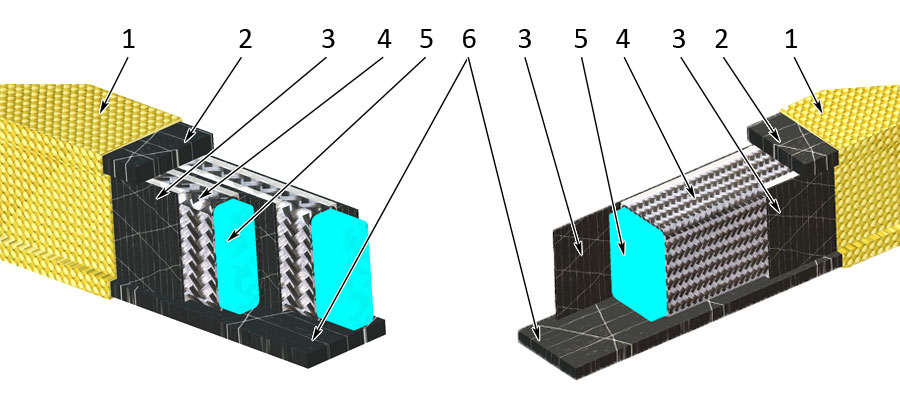

We manufacture two types of the wing spars for Supra central wing section:

Wing spars of Supra Hard Spread, Supra Glass and Supra Carbon-glass have 13 mm wide flanges

Wing spars of Supra Spread and Supra Glass Light Electric have 10.5 mm wide flanges

1 - the spar is enveloped in thin Kevlar fabric for improved durability;

2, 6 – the upper and the lower flanges are hot molded in an autoclave from carbon pre-preg IMS 65;

3 – the webbing is made from unidirectional carbon, which increases its strength against bending; induced buckling;

4 – carbon tubing of ±45° layup improves the torsional stiffness of the spar;

5 – the core is made from high strength foam.

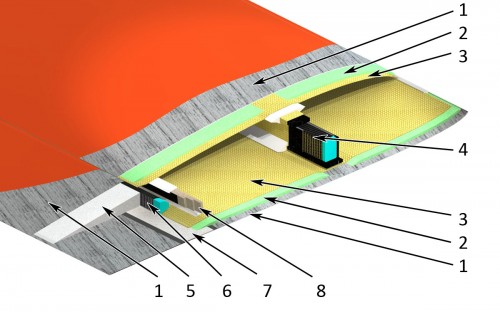

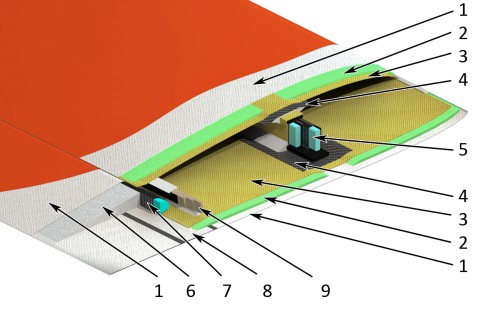

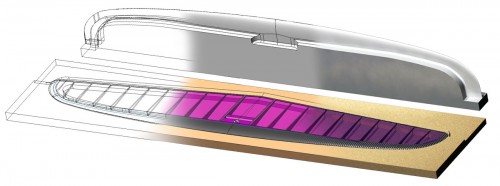

Versions of the wing design of Supra PRO and Supra Competition

Supra Spread central wing section

1 – outer layers of our carbon spread tow composite of ±30 degree layup ensure the wing’s high stiffness and strength;

2 – Herex core;

3 – inner layers of thin Kevlar at 45 degrees bias;

4 – spar flanges from high strength carbon IMS 65, 10.5 mm wide;

5 – flap core - Rohacell;

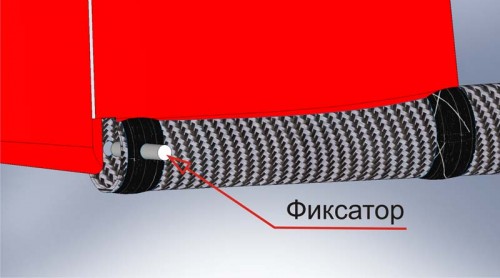

6 – flap spar from carbon braided sleeve, carrying torsional loads;

7 – strip of the hinge material;

8 – rear wall from balsa plywood covered with glass fabric.

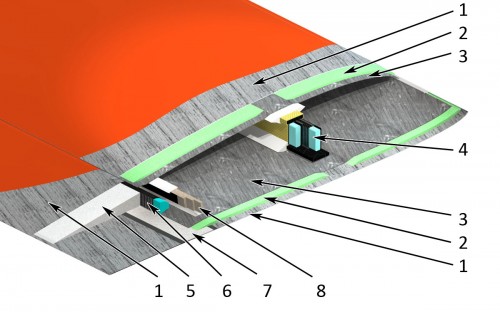

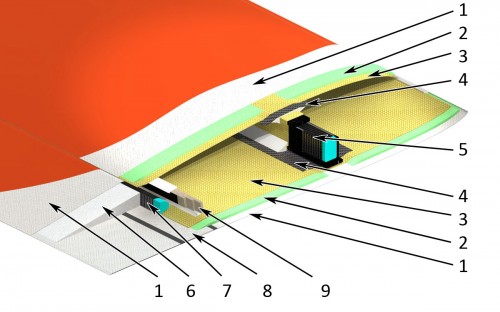

Supra Hard Spread central wing section

Replacement of Kevlar with Carbon in the inner layer substantially increases the wing stiffness.

1, 3 – outer layers of our carbon spread tow composite of ±30 degree layup ensure the wing’s high stiffness and strength;

2 – Herex core;

4 – spar flanges from high strength carbon IMS 65, 13 mm wide;

5 – flap core - Rohacell;

6 – flap spar from carbon braided sleeve, carrying torsional loads;

7 – strip of the hinge material;

8 – rear wall from balsa plywood covered with glass fabric.

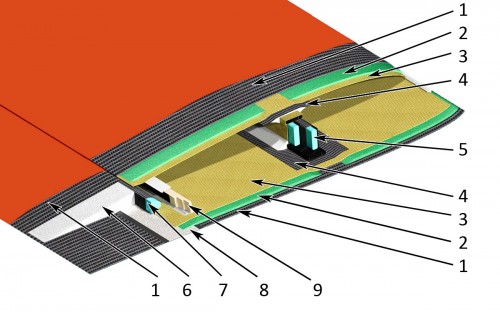

Supra Glass central wing section

1 – outer layers of thin glass composite of ±45 degree layup;

2 – Herex core;

3 – inner layers of thin Kevlar at 45 degrees bias;

4 – carbon reinforcements of the spar cut-outs;

5 – spar flanges from high strength carbon IMS 65, 13 mm wide;

6 – flap core - Rohacell;

7 – flap spar from carbon braided sleeve, carrying torsional loads;

8 – strip of the hinge material;

9 – rear wall from balsa plywood covered with glass fabric.

Supra Glass Light Electric central wing section

To reduce the weight of the less heavily loaded Electric version, its wing spar is made lighter.

1 – outer layers of thin glass composite of ±45 degree layup ;

2 – Herex core;

3 – inner layers of thin Kevlar at 45 degrees bias;

4 – carbon reinforcements of the spar cut-outs;

5 – spar flanges from high strength carbon IMS 65, 10.5 mm wide;

6 – flap core - Rohacell;

7 – flap spar from carbon braided sleeve, carrying torsional loads;

8 – strip of the hinge material;

9 – rear wall from balsa plywood covered with glass fabric.

Supra Carbon Glass central wing section

1 – outer layers of carbon composite of ±45 degree layup ensure the wing’s high stiffness and strength;

2 – Herex core;

3 – inner layers of thin Kevlar at 45 degrees bias;

4 – carbon reinforcements of the spar cut-outs;

5 – spar flanges from high strength carbon IMS 65 13 mm wide;

6 – flap core - Rohacell;

7 – flap spar from carbon braided sleeve, carrying torsional loads;

8 – strip of the hinge material;

9 – rear wall from balsa plywood covered with glass fabric.

Comparison of Supra family wings |

||||

|

Wing version |

Spread |

Hard Spread |

Glass |

Carbon-Glass |

|

Width of spar |

10,5 mm |

13 mm |

13 mm |

13 mm |

|

Composite sandwich of the central section |

Spread tow carbon- Kevlar |

Spread tow carbon- Spread tow carbon |

Glass- Kevlar |

Carbon- Kevlar |

|

Weight of the central section |

540 g |

575 g |

560 g |

620 g |

|

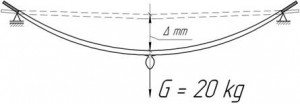

Bending deflection of the central section |

25,5 mm |

20 |

23,9 mm |

21 |

|

Composite sandwich of the wing tips |

Spread tow carbon- glass |

Spread tow carbon- glass |

Glass- Kevlar |

Glass- Kevlar |

|

Weight of a wing joiner (1 pc) |

17.1 |

19.8 |

||

|

Type of the wing joiner |

narrow (width 10mm) |

standard(width 11.5 mm) |

||

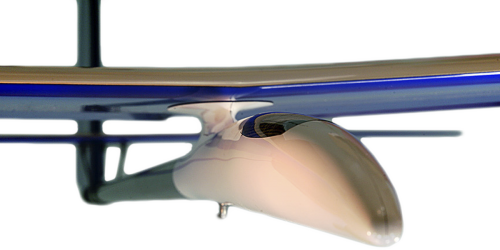

The new fuselage of Supra PRO satisfies a number of contradictory requirements:

1) The glider does not slide after landing but stops as soon as the nose touches the ground. The shape of the pod tip satisfies F3J requirements;

2) The fuselage has minimal aerodynamic drag, thanks to the wing raised on a pylon and streamlined pod outline with CFD optimized cross-sections;

3) The shape of the fuselage also ensures increased stiffness and strength, required for violent landings.

The fuselage of Supra PRO is optimized for the ease of the radio equipment installation and maintenance. The servos are installed on a removable tray, which permits easy access to the receiver and the battery.

The fuselage of the Electric version is described at electric page.

Tail boom

The tail boom is made of two layers of Spread Tow carbon laid up at ±45 degrees. Between the two Spread Tow layers, there is a longitudinal layer of the unidirectional carbon. This design resulted in extremely stiff and light boom—the weight of the tail boom without pushrods is only 41 gram.

Supra is shipped with finished fuselage pod, you only need to glue the nose and the tail boom together

Tow hook

Our trademark adjustable tow hook allows for launch optimization for any weather or C.G. location in the recommended range.

Canopy

The canopy is molded carbon composite. It uses reliable mounting latch design proven in many Vladimir’s Model planes: Blaster 2 electric, Sprite, Graphite 2 electric, Supra electric.

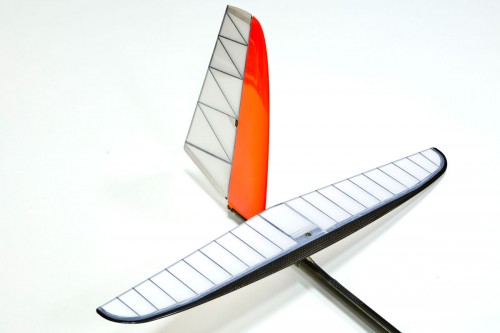

The main advantage of the new built-up stabilizer of Supra Competition is the improved landing accuracy.

We achieved that by reducing the plane inertia:

- The 7 gram reduction of the stabilizer weight resulted in 15 gram reduction of the nose ballast.

- The horizontal stabilizer area is increased by 7%.

- The vertical stabilizer is also 10 gram lighter, which allowed us to remove another 23 grams from the nose.

- The stiffnes and sthrength of the stabilizer is increased due to the use of D-box from high strength IMS 65 carbon fabric.

-The airfoil is extremely accurate for built-up structures, thanks to comprehensive CAD/CAM design and manufacturing procedures

Supra Pro Competition horizontal stabilizer

Our new CAD/CAM design and manufacturing processes resulted in extremely accurate built-up horizontal stabilizer, which has as low aerodynamic drag as the molded structure.

Vertical stabilizer

Supra has a detachable vertical stabilizer, which can be removed to facilitate transportation. The stabilizer is fixed on the tail boom with a carbon pin. It is recommended to secure the pin with a piece of scotch tape before flying.

The rudder of Supra Competition is of ultra light built-up defing.

The rudder of Supra PRO is of rearlier molded design with Rohaccell core and is a bit heavier.

The weights can be compared in technical data table.

Supra PRO Competition – the plane for winning!

Aerodynamic design by Dr. Mark Drela uniquely combines high penetration with the ability to catch even the weakest thermals using super efficient wing mechanization.

Accurate landings are easier to achieve, thanks to ultra light tail feather. The use of new materials and advanced design resulted in considerable weight reduction of the horizontal and vertical stabilizers, which substantially decreased the tail inertial.

The unique flight traits of Supra Competition are complemented by the streamlined fuselage, which instantaneously stops the plane at 100 point mark.

Our continuing efforts towards design optimization make the plane stronger and lighter with each new iteration.

Supra PRO – a good sailplane for achieving serious results.

Dr. Drela’s original design is complemented by a modern fuselage helping with precise landings.

Molded horizontal stabilizer originally developed by Dr. Drela still has a strong following.

A set of wing joiners for three different dihedral angles makes this model even more versatile, allowing for fine tuning for different flying conditions and your personal flying style.

Further information about the unique Supra Pro family construction see at technology bookmark.

You can selected parameters you need using the following comparative table.

|

Comparison of Different Models from Supra Family |

||||||||

|

Color the model |

SUPRA PRO Competition |

SUPRA PRO |

||||||

|

Model version |

Spread |

Hard Spread |

Glass |

Carbon-glass |

Spread |

Hard Spread |

Glass |

Carbon-glass |

|

Aerodynamic parameters |

||||||||

|

Length |

1700 mm (66,93") |

|||||||

|

Wing span |

3400 mm (133,85") |

|||||||

|

Wing area |

69,34 dm2 (1052 in2) |

|||||||

|

Wing airfoil |

AG 40/ AG 41/ AG 42/ AG 43 |

|||||||

|

Wing aspect ratio |

16.67% |

|||||||

|

Horiz. stabilizer area |

6,2 dm2 (96,1 in2) |

5,8 dm2 (89,9 in2) |

||||||

|

Horiz. stabilizer aspect ratio |

7.68% |

7.74% |

||||||

|

Horiz. stabilizer airfoil |

HT 14/ HT 15 |

|||||||

|

Vertical stabilizer area |

4,9 dm2 (76 in2) |

|||||||

|

Vertical stabilizer airfoil |

HT 13/ HT 12 |

|||||||

|

Vertical stabilizer aspect ratio |

2.5% |

|||||||

|

Control surfaces |

ailerons, flaps, full-flying stabilizer, rudder |

|||||||

|

Weights, gr** |

||||||||

|

Pod |

190 |

|||||||

|

Tail boom with pushrods and V-mount |

68 |

|||||||

|

Wing central section (with wires) |

540 |

565 |

585 |

730 |

540 |

565 |

585 |

730 |

|

Pair of wing tips |

330 |

356 |

350 |

330 |

356 |

350 |

||

|

Vertical stabilizer & rudder |

33 |

40,5 |

||||||

|

Horizontal stabilizer |

26,3 |

34,6 |

||||||

|

Fairings, control horns, etc. |

82 |

|||||||

|

Empty airframe |

1259,3 |

1330 |

1340 |

1440 |

1345 |

1410 |

1425 |

1525 |

|

AUW (All Up Weight) * |

1530 |

1590 |

1600 |

1700 |

1615 |

1675 |

1685 |

1785 |

|

Wing loading,g/dm2 * |

22 |

23 |

23 |

24,5 |

23,3 |

24,1 |

24,3 |

25,7 |

|

Price, EUR |

||||||||

Top

Top

.jpg)